Cleatech Glove Boxes

Cleatech manufactures glove box systems both standard and custom that maintain specific environmental conditions. We offer custom solutions when it comes to sizes or glove ports to meet increasing space requirements. Our design philosophy combines robust manufacturing practices with state-of-the-art engineering technology providing units that are customizable, efficient, and of the highest caliber.

Glove Box Structure:

Major components of a typical glove box contain a:

- Main Chamber:This is the enclosed environment with arm ports where the procedures are performed. The chambers are also modified for more people operating on the same system.

- The Antechamber:Also known as airlock is the unit that is attached to the side of the main glove box chamber. The main use of this unit is to form a barrier between inside and outside while transferring samples.

- The Atmosphere Control Unit:This unit helps in controlling the conditions inside the chamber. For example, inert gas purge system to control moisture and oxygen concentration, filtration/purification system to remove particles or fumes and temperature control system to heating and refrigeration.

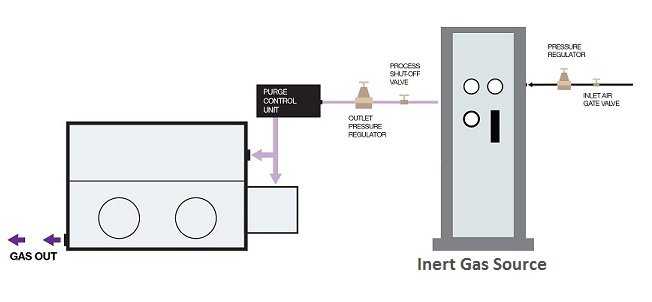

1. Glove Box: Moisture & Oxygen Control

In this type of box the internal air is first removed and then replaced by inert gases such as argon or nitrogen which do not react with most chemicals. These gases are harmless in nature and do not react with the chemicals and samples. These boxes also remove moisture and o2 from the atmosphere to protect samples from oxidation This is why these boxes are also called dry boxes, anaerobic boxes, nitrogen boxes

| Standard Size | Small Size |

| 2100 Series Glove Boxes: >Two-port Standard 35″Wx24″Dx25″H >Four-port Standard 60″Wx24″Dx25″H >Four-port Back-to-Back 35″Wx36″Dx25″H |

2200 Series Glove Boxes:>Two-port Portable 27″Wx18″Dx18″H 2500 Series Glove Boxes:>Two-port Compact 16″Wx16″Dx16″H |

2. Glove Box:Particle Control – Open Loop

These glove boxes provide complete separation from the outside environment inside an enclosed space, but they do not have a different atmosphere. Filtered glove boxes are used to capture and filter particulates from the inside environment or prevent outside particulates from entering the enclosed space. These particulates can be any contaminant such as dust, bacterial or even aerosols. Gases, however, cannot be contained by these glove boxes and thus are free to travel, therefore the moisture and oxygen level and temperature cannot be controlled.

3. Glove Box:Particle & Atmosphere Control – Closed Loop

These boxes are not directly open to the outside atmosphere and the air inside is filtered after several rounds of circulation through the HEPA or ULPA filters. These closed-loop glove boxes provide a more efficient way to filter all the harmful and are good for any application requiring an inert gas environment. A more advanced model is also available so the valves can convert the closed-loop to an open-exhaust system.

| Open Loop | Close Loop |

| 2300 Series Glove Boxes: >Two-port Standard 35″Wx24″Dx25″H >Four-port Standard 60″Wx24″Dx25″H |

2400 Series Glove Boxes: >Two-port Standard 35″Wx24″Dx25″H >Four-port Standard 60″Wx24″Dx25″H |

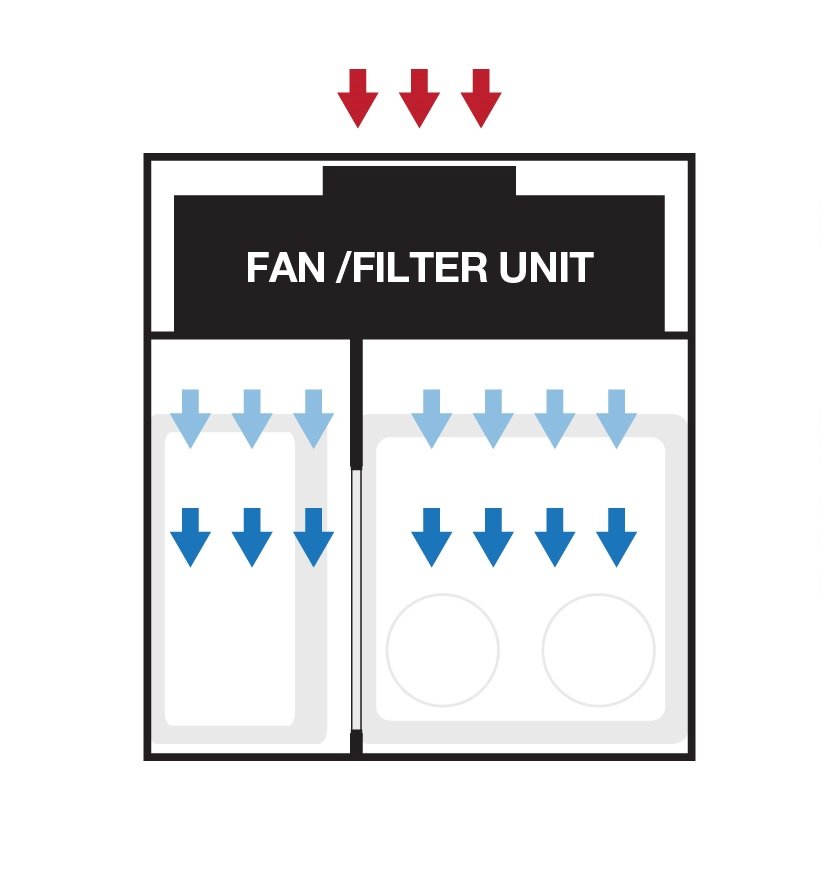

4. Glove Box:Particle Control – ISO5 Isolator

The supply HEPA filter provides laminar flow air, which showers the entire work area of the main and antechamber. They are an economical solution for compounding pharmacies to meet the performance criteria for USP 797 and any other application require ISO class 5 conditions.

Cleatech manufactures standard and custom glove boxes for applications require clean, dry and oxygen-free environment.